Diaphragm walls for top-down construction and deep basements have now become commonplace in the industry, and among construction companies in India. But how did D-Wall construction (another name for diaphragm walls) become a popular choice with civil engineers who are now confident to build towering superstructures with basements as deep as 5 levels?

Let us begin by understanding what a diaphragm wall is, how it is different from other traditional methods of ground engineering like Piling, and what makes it a desirable choice for deep basement construction.

What is a diaphragm wall?

Reinforced concrete walls built in the ground to provide support to the structure to be built above, and act as walls for the deep basement space to be built later, are known as diaphragm walls. They act as the cut-off walls for the excavated area of the site, provide a strong foundation to the surface and enclose the structure.

Piling – The traditional method of deep foundation construction

Piling is one of the oldest methods of building foundational bases for under-construction structures to transfer and manage the structural load on a deeper level. They are long, cylindrical structures that are made of either concrete, wood or steel.

There are two types of pile foundations used in building strong bases

1. End-bearing piles, that can transmit weight load directly to the deeper, stronger soil or the rock base of the site.

2. Friction piles, which transfers the load of the building to the soil across the full height of the pile, by friction.

Piling, a traditional method, is used when the structure above has heavy, concentrated loads and the spread footing won’t be able to bear the weight. So the building structure needs to bypass this layer and transfer the weight to the stronger base at depth.

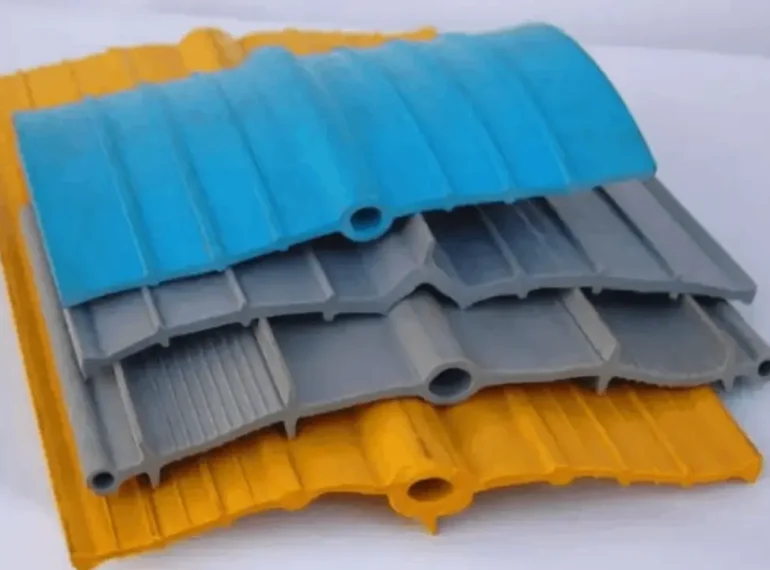

While a diaphragm wall is constructed by excavating a narrow trench with a thickness ranging between 300 mm to 1200 mm, as deep as 45 metres underneath. It actually does the exact same job, and moreover, offers to act as a retaining wall for the basement, making the foundation stronger.

Yet, what makes construction companies in India choose diaphragm walls for basements?

Lower steel consumption

The cage walls made for diaphragm wall construction require lesser steel bars compared to constructing and inserting piles into the ground below. And in scenarios of unstable soil on the site, an additional casing is required on the piles, which may add an extra cost to the materials consumed.

Fewer joints are required than piling

D-wall construction takes two to four joints to hold positions in the area to be excavated. Cylindrical piles have gaps among them ranging between 15 to 50mm, and the longer the basement wall is supposed to be, the more piles are required, which results in additional joints between each pile.

Reduced water leakage risks

A running diaphragm wall is known to prevent water leakages better than other forms of basement wall construction. There are always gaps between the planks on the piles, meaning the water tightness of a d-wall construction is better comparatively. It is important to have waterproofing done every time piling construction is used in basement construction.

Tilting/fall risk is lower

Piles are driven, hammered or vibrated directly into the ground prior to excavation, which means the verticality of the piles may not be at the correct angle. This could lead to the base getting unstable due to the tilt and may stand the risk of falling. In diaphragm wall construction, the soil is excavated in the precise length and depth required, filled with polymer slurry and the concrete is added to form the wall structure and anchored down to ensure its stability.

Cost-effective

Piling requires the construction of an additional retailing wall for better finishing and support to the structure. Further, anchoring becomes all the more complex with pile foundations. These factors add to the cost of the project and reduce margins

Heritage Infraspace – Pioneers of Diaphragm Wall Construction in India

Having seen how the quality of work and safety of workers were taken with utmost seriousness in underground projects, Mr. Gagan Goswami, the founder of Heritage Infraspace India Ltd, started to use diaphragm walls in India for deep basement construction for various residential and commercial infrastructure projects like housing complexes, business parks, metro rail construction and dams.

Diaphragm walls are now commonly used while constructing structures with deep basements in congested areas, as they can be installed in close proximity to the existing structures. HIPL uses state-of-the-art excavators and rigs sourced from Italy, which helps them complete the projects on time and ensure high standards in their work.

HIPL as a responsible construction company in India also puts its efforts towards imparting knowledge and spreading awareness about the pros of using d-wall construction for modern structures, in the form of training for young civil engineering students, exposure to the teams in innovative ground engineering practices in diaphragm wall for top-down construction.

To learn more about our projects, success stories and various geotechnical engineering solutions for construction companies in India, email us on info@www.heritageconstruction.in.