What is an Anchor System in Construction?

An anchor system in construction is a method of connecting structural and non-structural elements to the concrete using ground anchor bolts. These bolts are part of an assembly that includes steel plates, stiffeners and other components.

The anchor system helps to transfer tension and shear forces between the connected elements, enhancing the stability and strength of the structure. At Heritage Infraspace, a diaphragm wall construction company in India, we use the most advanced anchoring rig (Casagrande C6) to install ground anchor systems efficiently and effectively. This helps us to reduce project costs, time and quality issues.

Types of anchors used in underground construction

There are two types of ground anchor systems widely used for diaphragm wall construction: traditional anchors and retractable anchors.

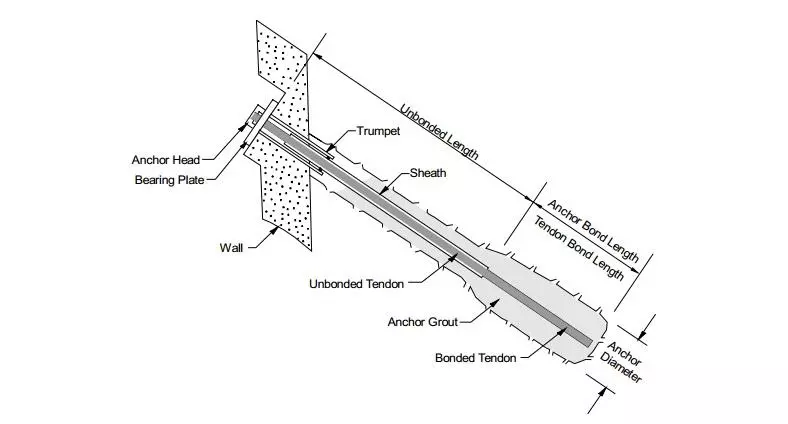

Traditional anchors are fixed in the ground and cannot be removed or repositioned after the construction process is complete. They consist of steel tendons or bars that are placed inside pre-drilled holes in the ground and filled with grout. The other end of the anchor is attached to the diaphragm wall reinforcement cage to provide lateral support.

Retractable anchors are flexible and can be easily removed or repositioned without damaging the surrounding soil or structures. They also consist of steel tendons or bars that are placed inside pre-drilled holes in the ground and filled with grout. However, the tendons or bars can be retracted from the grouted hole by using a special device. The other end of the anchor is also attached to the diaphragm wall reinforcement cage to provide lateral support.

Retractable anchor system in construction offer many benefits such as saving resources, adapting to different soil conditions, and avoiding conflicts with neighbouring properties. Heritage Infraspace India Ltd., one of the top civil engineering companies known for diaphragm wall construction in India, specialises in diaphragm wall construction using retractable anchors. They use steel tendon grouted ground anchors manufactured by Tata and Usha Martin.

Importance of Ground Anchors in underground construction

Diaphragm walls alone are not enough to withstand the horizontal pressure from the soil and water. Therefore, ground anchor systems are used to connect the diaphragm walls to the ground and provide lateral support.

Anchor system in construction offer many benefits for diaphragm walls, such as:

- Improved safety: Ground anchors help to prevent the collapse of diaphragm walls by providing lateral stability and resistance to external forces.

- Reduced cost: Ground anchors can eliminate the need for other types of support, such as struts and braces, which can reduce the cost of diaphragm wall construction.

- Reduced construction time: Ground anchors can allow for faster excavation and concrete pouring, which can reduce the construction time for diaphragm wall projects.

- Improved flexibility: Ground anchors can support a variety of diaphragm wall configurations, including straight walls, curved walls, and stepped walls.

To ensure the quality and durability of diaphragm wall construction, it is also important to use PVC water stoppers. Water stoppers or Water Bars are flexible strips that are embedded in the joints of diaphragm walls to prevent water leakage and seepage and protect the concrete from corrosion and cracking.

The Process

An anchor system in construction is a method of connecting structural elements to the ground using ground anchor bolts. These bolts are part of an assembly that includes steel plates, stiffeners, and other components.

The process for ground anchoring system in diaphragm wall construction involves the following steps:

- A drill rig is used to drill boreholes of 150 to 180 mm diameter at an angle of 15 to 30 degrees from the vertical plane.

- A low relaxation prestressed steel (LRPC) strand is inserted into the borehole as the anchor tendon.

- The borehole is cleaned with compressed air and filled with grout to bond the anchor tendon with the soil.

- The anchor head is pre-tensioned by jacking after 7 to 10 days of curing and fixed to the diaphragm wall reinforcement cage.

- The anchor is later de-stressed after the slab casting is done.

To improve the bearing capacity and settlement characteristics of the soil, vibro stone columns can also be used along with ground anchors. They can increase the stiffness and strength of the soil, reduce liquefaction potential, and enhance drainage.

Solutions we provide

At Heritage Infraspace India Ltd., we offer a range of solutions for anchor system in construction, such as:

- Cast-in anchors: This ground anchor system is embedded in the concrete during the casting process. They include headed bolts, hooked bolts, and headed studs. Cast-in anchors are suitable for high-load applications and offer reliable performance.

- Post-installed anchors: These are anchors that are installed in the concrete after it has hardened. They include expansion anchors, undercut anchors and adhesive anchors. Post-installed anchors are suitable for low to medium-load applications and offer flexibility and versatility.

- Lateral support: We provide lateral support to the diaphragm wall to sustain force from the top. This can be achieved by using struts, braces, or tiebacks. Lateral support can improve the safety and efficiency of diaphragm wall construction.

To ensure the quality and durability of diaphragm wall construction, we also use high-quality ready-mix concrete supplied by our own ready mix concrete supplier at Hebatpur in Ahmedabad. trusted partners. Ready mix concrete is concrete that is prepared in our batching plant and delivered to the site in a ready-to-use condition. Ready-mix concrete can save time, money and resources, as well as ensure consistent quality and performance.

Frequently Asked Questions

Some of the advantages of diaphragm wall construction are:

It can provide a watertight and durable underground support for structures, and reduce noise and vibration during excavation and construction. It can save space and resources by eliminating the need for temporary shoring or sheet piling. It can allow for greater design flexibility and creativity.

It can be expensive and time-consuming compared to other methods. It can require skilled labour and specialized equipment. It can pose technical challenges and risks such as soil collapse, water leakage, or concrete defects.

The duration of diaphragm wall construction depends on various factors such as the size, depth, shape, and complexity of the wall, the soil conditions, the weather, the availability of materials and equipment, and the quality control measures. The average time for diaphragm wall construction is about 2 to 4 weeks per panel, where a panel is a section of the wall that is cast in one operation. However, this time can vary depending on the specific project requirements and circumstances.