Diaphragm wall construction, a crucial aspect of modern infrastructure projects, demands precision, speed and quality. In this context, the integration of Ready Mix Concrete in India has emerged as a game-changer, redefining the efficiency and effectiveness of diaphragm wall construction in India. In this blog, we will delve into the myriad benefits that RMC offers over traditional on-site concrete mixing methods, showcasing how it has reshaped the construction landscape.

Advantages of RMC in Diaphragm Wall Construction

Speed and Efficiency Enhancement: Incorporating RMC streamlines the construction process by eliminating the need for on-site concrete mixing. The availability of pre-mixed concrete, manufactured in RMC Plants, ensures a swift and seamless flow of construction activities. This enables construction companies in India to meet project timelines more efficiently, especially in projects like metro diaphragm wall construction and top-down construction.

Scenes from diaphragm wall construction by HIPL in Ahmedabad

Consistent Quality and Strength: RMC production involves meticulous control over concrete proportions and mix design. This level of precision guarantees consistent quality and strength, reducing the risk of structural deficiencies. In diaphragm wall construction, where the integrity of the structure is paramount, RMC’s uniformity contributes significantly to the durability and longevity of the walls. As one of the premium RMC suppliers in India, HIPL provides high-quality RMC. Subway construction companies in India often use our RMC for diaphragm wall construction.

Realising Time and Cost Savings: Two remarkable projects exemplify the transformative impact of the utilisation of Ready Mix Concrete in India for diaphragm wall construction. The Sovereign Project by Ashima Group in Thaltej stands as a testament to RMC’s ability to accelerate top down construction while maintaining impeccable quality. Similarly, the DJ Toyota Ognaj Showroom project showcases how RMC not only expedites the construction process but also results in substantial cost savings.

Advanced Batching and Mixing Technology

At the heart of RMC’s success lies advanced batching and mixing technology. RMC Plants, like the 2 HIPL plants in Hebatpur with a 60 cubic meters per hour and 120 cubic meters per hour capacity, incorporate innovative features such as chiller plants. These plants regulate concrete temperature, optimising the heat of hydration. This commitment to precise RMC temperature control is crucial to big projects metro diaphragm wall construction in India. Here’s why…

Ensuring Structural Integrity: The precise control afforded by HIPL production technology as RMC suppliers in India translates to enhanced structural integrity in diaphragm walls. The correct mix of design and proportion ensures that the walls can withstand external forces, ensuring the safety of the overall infrastructure. As India embraces ambitious water supply projects, RMC’s role in diaphragm wall in dams guarantees structural soundness and it becomes indispensable.

Scenes from Delhi Metro station diaphragm wall construction by HIPL

Environmental Sustainability: In an era where sustainability takes centre stage, RMC’s advantages extend beyond construction efficiency. The reduced environmental impact of RMC production compared to on-site mixing aligns with the eco-conscious goals of modern construction practices. This shift towards more sustainable methods contributes to India’s broader environmental efforts.

Challenges and Limitations

One challenge is that RMC is more expensive than on-site concrete mixing. This is because RMC plants have to be located near the construction site and the concrete has to be transported to the site.

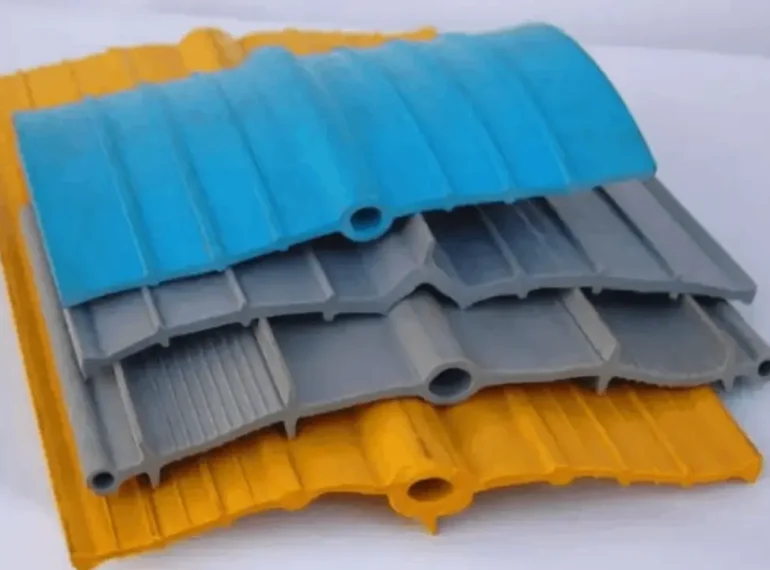

Another challenge is that RMC can be more difficult to pump than on-site concrete. This is because RMC is more viscous and it can be more difficult to get the concrete to flow through the tremie pipes.

Finally, RMC can be more susceptible to segregation than on-site concrete. This is because RMC is mixed in a central plant and the concrete can be exposed to vibration during transportation.

Despite these challenges, RMC offers several advantages over on-site concrete mixing for diaphragm wall construction. RMC is a more consistent concrete, which can improve the quality of the wall. RMC is also a more durable concrete, which can extend the lifespan of the wall.

In addition, RMC can be used to make vibro stone columns, which are a type of ground improvement technique that uses concrete to improve the bearing capacity of the soil. Vibro stone columns are often used in foundation construction, but they can also be used for other purposes, such as slope stabilisation.

The Future of RMC Technology

Looking ahead, the evolution of RMC technology promises even greater efficiency and innovation in diaphragm wall construction. As construction companies in India continue to push boundaries, RMC’s role as a catalyst for progress will only strengthen. Advanced automation, data-driven insights and further sustainability enhancements will shape the next phase of RMC’s usage by diaphragm wall engineers and piling contractors in India.

Conclusion

HIPL’s commitment to quality is reflected in its RMC plants, equipped with advanced features such as chiller plants for temperature control. With a capacity of 3000 to 4000 cubic meters per month, Heritage’s RMC plays a pivotal role not only in their projects but also in serving third-party clients.

Frequently Asked Questions

Ready mix concrete (RMC) is a mixture of cement, water, aggregates and admixtures. Admixtures are chemicals that are added to concrete to improve its properties, like water reducers, Air-entraining admixtures and Corrosion inhibitors.

Aggregates are the inert materials that make up the bulk of concrete. The most common aggregates used in RMC are sand, gravel and crushed stone. The type of aggregate used depends on the strength and durability requirements of the concrete.

Ready mix concrete should be discharged from the truck mixer or agitator truck within two hours of mixing. If non-agitating transporting equipment is used, this time is reduced to one hour. All delays must be avoided to prevent honeycombing or cold joints.