Diaphragm wall construction is revolutionising India’s urban landscape by enabling robust underground construction. These reinforced concrete walls provide a sturdy barrier against soil and water, laying a secure foundation for various structures. For basement construction in India, they optimise space utilisation in densely populated cities beneath malls, hospitals and parking lots.

The future of diaphragm walls in India is filled with opportunities and challenges, with new technologies shifting the dynamics of the field. In this blog, we’ll explore the latest trends and forecasts and how this technology is transforming India’s subterranean development. Read on to explore d-wall, as we talk about the trends, challenges and the transformative impact of this technology.

Major trends shaping the future

The construction industry is undergoing a rapid transformation due to the advancement of technology and innovation. Some of the major trends influencing the development of basement diaphragm wall are below.

Technological advancements

Automation and robotics: Automation and robotics are being increasingly used to improve the efficiency, accuracy and safety of excavation and construction processes. For example, robotic arms and machines can be used to drill, cut and install the diaphragm wall panels, reducing the need for manual labour and human intervention. Automation and robotics can also help to monitor the quality and performance of the d-wall, as well as to detect and repair any defects or damages.

Digital twins and BIM: Digital twins and building information modelling (BIM) are digital representations of physical structures and systems that can be used to optimise the design of basement construction details in India and the execution of diaphragm wall construction. Digital twins and BIM can enable real-time data collection and analysis, as well as simulation and testing of various scenarios and conditions. Digital twins and BIM can also facilitate collaboration and communication among the stakeholders involved in the diaphragm wall project, such as engineers, contractors and clients.

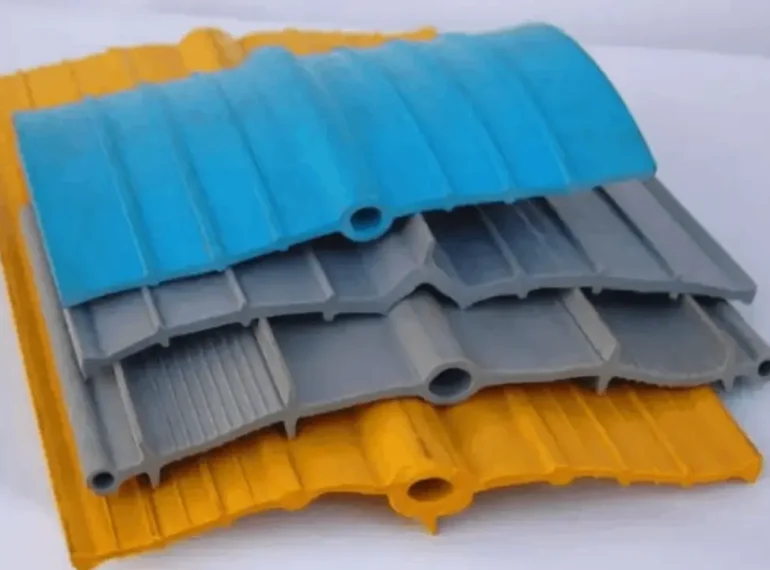

Innovative materials and techniques: Innovative materials and techniques are being developed to enhance the performance and durability of basement diaphragm wall. For instance, self-healing concrete is a type of concrete that can repair itself when exposed to water or air, thus increasing its resistance to cracking and corrosion. Advanced waterproofing systems are also being implemented to prevent water leakage and seepage through the diaphragm wall joints and cracks, thus improving the structural integrity and longevity of the basement.

Sustainability and environmental concerns

Basement diaphragm wall are not only beneficial for creating more space and value in urban areas but also for promoting sustainability and environmental protection. Some of the ways that basement diaphragm wall can contribute to these goals are as below.

Use of recycled materials and green construction practices: Recycled materials and green construction practices can help to reduce the environmental impact and carbon footprint of basement diaphragm wall. For example, bentonite can be recycled and so can steel and plastic to make the diaphragm wall panels during its construction, thus saving natural resources and energy. Green construction practices can also involve the use of renewable energy sources, such as solar and wind power, to power the excavation and construction equipment, thus reducing emissions.

Focus on reducing noise and vibration pollution during construction: Noise and vibration pollution are common issues that arise during the construction of deep basements, especially in densely populated areas. Noise pollution can cause disturbance and annoyance to the nearby residents and businesses, as well as damage to the surrounding buildings and infrastructure. Therefore, it is important to adopt measures to reduce noise and vibration pollution during construction, such as using low-noise and low-vibration equipment, installing noise barriers and vibration isolators and implementing noise and vibration monitoring and control systems.

Energy-efficient excavation and transportation methods: Energy-efficient excavation and transportation methods can help lower the energy consumption and cost of basement diaphragm wall construction. For example, hydraulic excavators and cranes can be used to dig and lift the soil and the diaphragm wall panels, instead of diesel-powered machines, thus reducing fuel consumption and emissions. Energy-efficient transportation methods can also involve the use of electric or hybrid vehicles, as well as the optimisation of the routes and schedules, to transport the materials and equipment to and from the construction site, thus minimising travel distance and time.

Market demand and applications

Basement diaphragm wall have a wide range of market demand and applications in various sectors and regions. Some of the factors that drive the demand and applications of basement diaphragm wall are:

Growing demand for deep basements in urban areas: As urbanisation and population growth continue to increase, there is a growing demand for deep basements in urban areas, as they can provide more space and functionality for various purposes, such as parking, storage, utilities and amenities. Basement diaphragm wall are ideal for creating deep basements, as they can withstand high lateral loads and water pressures, as well as provide stability and safety for the excavation and construction workers.

Integration with other infrastructure projects: Basement diaphragm wall can also be integrated with other infrastructure projects, such as metro stations and high-speed rail, to create multi-functional and interconnected spaces. For example, basement diaphragm wall can be used to form underground tunnels and stations for the metro and rail systems, as well as to connect them with the above-ground buildings and facilities. Basement diaphragm wall can also enhance the efficiency and convenience of the transportation and mobility systems, as well as the accessibility and connectivity of urban areas. Moreover, the application of a diaphragm wall in dam construction can significantly enhance the structural integrity and safety of the dam.

Predictions and challenges

The trends that are shaping the future of diaphragm wall construction have a significant impact on the industry and society. Some of the possible impacts are:

Enhanced performance and efficiency

The use of new technologies and innovations can improve the performance and efficiency of d-wall construction, such as reducing construction time and cost, increasing quality and durability and optimising the design and operation.

Increased value and functionality

Integrating diaphragm wall construction with other infrastructure projects can increase the value and functionality of the underground spaces, such as providing more parking, storage, utilities and amenities, as well as enhancing transportation and mobility systems.

Improved sustainability and resilience

The adoption of green construction practices and resilient design methods can improve the sustainability and resilience of diaphragm wall construction, such as reducing the environmental impact and carbon footprint, mitigating noise and vibration pollution and protecting against natural hazards and disasters.

However, diaphragm wall construction also faces some challenges that need to be addressed and overcome. Some of the potential challenges are:

Skilled labour shortage

Diaphragm wall construction requires skilled and experienced labour to perform complex and challenging tasks, such as drilling, cutting and installing the diaphragm wall panels. However, there is a shortage of skilled labour in the construction industry, due to the ageing workforce, low retention rate and lack of training and education.

These differences mean that diaphragm walls and slurry walls have different advantages and disadvantages, depending on the project requirements and site conditions. Diaphragm walls are more suitable for projects that require high-quality and long-lasting walls, such as tunnels, basements, dams and underground structures. Slurry walls are more suitable for projects that require low-cost and quick walls, such as temporary earth retention and water control.

Rising material costs: Diaphragm wall construction involves the use of large amounts of materials, such as concrete, steel and plastic, to produce the diaphragm wall panels. However, the material costs are rising due to the increasing demand, limited supply and fluctuating market prices.

Regulatory hurdles: Diaphragm wall construction has to comply with various regulations and standards, such as safety, quality and environmental regulations, as well as planning and zoning laws. However, the regulations and standards are often complex, inconsistent and outdated, which can cause delays, disputes and penalties.

Some concluding thoughts

The future of diaphragm wall is bright and promising, as they can leverage new technologies and innovations, such as automation, robotics, digital twins, BIM, self-healing concrete and advanced waterproofing systems, to enhance their performance and efficiency. Diaphragm wall are already being integrated with other infrastructure projects, such as metro stations and high-speed rail, to create multi-functional and interconnected spaces.

As a leading and trusted company in diaphragm wall construction, with a proven track record of delivering high-quality and cost-effective projects across India, Heritage Infraspace too is committed to building on such innovation and expertise, as it constantly strives to improve its processes, products and services and to meet the needs and expectations of its stakeholders.

Frequently Asked Questions

Diaphragm walls are reinforced concrete walls constructed in the ground using an under-slurry technique developed in Europe. These walls are generally used for constructing structures with deep basements in congested areas, as they can be installed close to existing structures. The walls are formed by excavating a narrow trench that is kept full of an engineered slurry fluid. This way, concrete diaphragm walls with thickness ranging between 300 mm to 1200 mm can be formed as deep as 45 metres underneath. Inclined rock or soil anchors are used for this purpose.

Retaining walls are used to retain soil or other materials, while diaphragm wall are used to create a barrier between two areas. Retaining walls are typically constructed above ground, while diaphragm wall are constructed below ground. Diaphragm wall are also more flexible in terms of their plan layout and can be easily incorporated into permanent commercial and residential projects.

Diaphragm walls are an economical and positive solution for large deep basements in saturated and unstable soil profiles. They can be installed to a considerable depth with the formation of walls with substantial thickness. Diaphragm walls are designed to carry vertical loads, thus reducing the construction time of the basement. Further, the noise levels are limited to the engine noise only and there’s no vibration during its installation.