Some of the strongest and biggest structures in the world are built on much smaller, but crucial items which hold the foundation of their strength. And when it comes to building diaphragm walls for underground basements, one of the biggest concerns for any civil engineer is water seepage on site. This is where water stoppers come into play in diaphragm wall construction.

What are Water Stoppers?

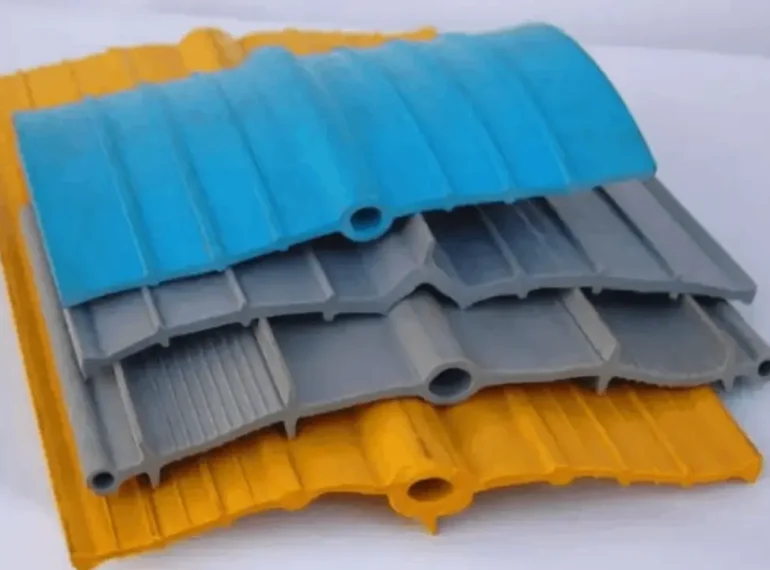

Water Stoppers are flexible strips made of plastic or rubber that act as a physical barrier to water at concrete joints, most commonly in basements, water retention structures such as tanks, swimming pools, structural foundations, and other underground buildings.

Water stoppers are also known as Water Bars, and are used to seal construction connections. As a top construction company in India, Heritage Infraspace produces its own water stoppers which help in saving massive material costs during the construction of the best concrete diaphragm walls in India.

Why is it important in underground construction?

A typical water stopper has two identical halves on both sides of a central bulb. These additional extensions are provided with the aim of increasing the path length for water entering behind the edge of the water stopper. They act as a sealant at the concrete joints and prevent any seepage of water in or out through joints. PVC Water stoppers can withstand a lot, ranging from the expansion or contraction movement at joints, any deflection or displacement arising due to change in temperature, differential settlement of the foundation, and even geo disturbances causing seismic forces like earthquakes, thus eliminating the danger of cracks.

How are water stoppers made?

Water Stoppers are made of Bentonite, a hydrophilic and absorbent swelling clay and polyvinyl chloride (PVC), a synthetic polymer of plastic known for its rigidity and flexibility. Bentonite is mixed with water then the resultant product is rolled and cut out in long, pulled-out strips depending on the required size.

This is followed by a series of sample tests and quality checks for expansion and water absorption. These long strips of water stoppers are then instilled into concrete joints during construction. HIPL, as a diaphragm wall construction company in Ahmedabad, India operates its own water stopper manufacturing unit located in Vatva, Gujarat. This Water Stopper Unit was established in 2020.

The Water Stoppers manufactured at HIPL’s unit are as per IS:15058/2002, based on a specifically formulated plasticized PVC composition.

How are Water Stoppers used in Diaphragm Wall Construction?

The best concrete diaphragm walls in India built for deep basement projects are constructed and set in the form of panels. These panels are set at about 5 meters apart from each other, and in this gap, stop ends are inserted to connect them.

A stop end tube with a smooth surface or a structural section shall be inserted in the trench at the end of the panel to support concrete and to form a suitable joint with the next panels.

Stop-ends are placed vertically at each end of the primary panel to form joints for adjacent secondary panels or closing panels. Panels are usually 4 to 6 meters long.

Stop-ends are used to form the joints between adjacent panels and a water stopper is incorporated across these joints. (See image on the side)

Once the diaphragm wall cages are lowered and the concrete is poured in, the diaphragm wall is allowed to set. Once sturdy enough, these stopends are pulled out, and the water stoppers seal the joints completely, preventing any form of water from seeping through the soil walls.

[Engineers’ Note: If there is a seepage due to the high water pressure in the excavated site, waterproofing is necessary and has to be done separately for the basement]

Can Diaphragm Walls be built without water stoppers?

No. Water Stoppers are one of the most crucial parts of the diaphragm wall construction in India. While earlier, every top construction company would prefer using the round stop ends on dry soil, with the innovation and the advent of diaphragm wall technology, pioneered by HIPL, water stoppers are now used in building both manual retaining walls and diaphragm walls for underground basements.

As water stoppers prevent water from seeping in, no matter how flush the water table of the soil is, the excavators can dig through and continue with their builds worry free.

HIPL has completed over 300 projects and built over 42 kilometers of diaphragm walls till date. Drop us an email on info@www.heritageconstruction.in to know more about what we do and how we could help your next big project become a landmark of strong and safe construction.