Anyone involved in civil engineering projects and worked in basement construction must have come across the terms slurry wall and diaphragm wall. These are two types of reinforced concrete walls constructed in trenches filled with a fluid mixture that stabilises the soil. They are widely used for soil retention, water control and foundation support in areas with high groundwater tables or soft soil. But what is the difference between a slurry wall and a diaphragm wall? Are they the same thing or not?

Here, we will explain the differences and similarities between these two types of walls, as well as their applications and advantages. We will discuss all about how they are constructed, what their characteristics are and how they compare and contrast with each other. By the end, we will provide a clearer understanding of these walls for deep basement construction.

What is a Slurry Wall?

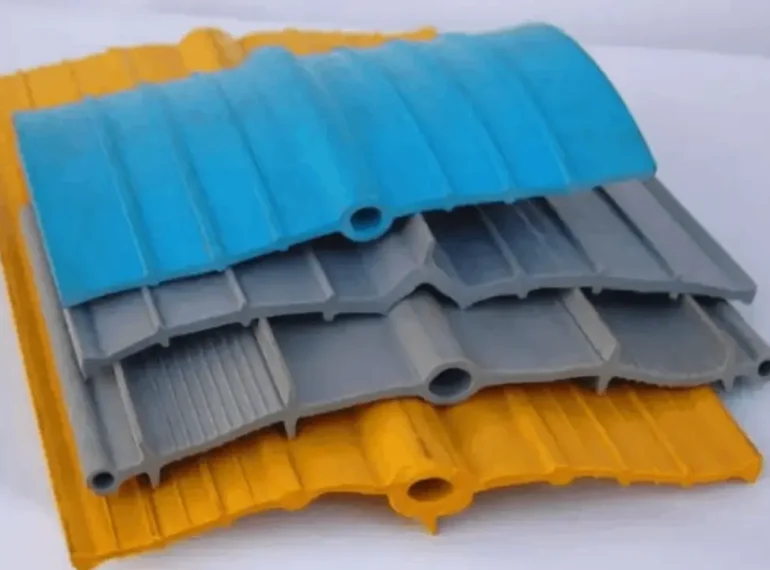

A slurry wall is a reinforced concrete wall, particularly used in top-down construction for deep permanent structures. A slurry wall is constructed in a trench that is filled with a fluid mixture, usually bentonite or polymer, that prevents the soil from collapsing. The fluid is then replaced by concrete that is poured from the bottom up using a pipe. The concrete wall acts as a barrier to water and soil pressure and can serve as a foundation or a structural element.

What is a Diaphragm Wall?

A diaphragm wall is a reinforced concrete wall that is constructed in situ under the ground. It is a continuous wall that can serve as a retaining structure, a cut-off wall, or a load-bearing element in various construction projects. Concrete diaphragm walls are typically constructed in panels that are interlocked to ensure structural stability and water tightness.

Differences between a Slurry Wall and a Diaphragm Wall

Although diaphragm walls and slurry walls are both types of reinforced concrete walls that are constructed in situ using slurry-supported trench excavation techniques, they have some notable differences that affect their performance and suitability for different projects. Here are some of the main differences between them:

Method of excavation

Diaphragm walls can be excavated using a hydromel or a cutter, which can create more precise and smooth walls and can also cut through hard soil or rock layers. Slurry walls are excavated using a mechanical clamshell or a hydraulic grab, which can create more irregular and rough walls and can only cut through soft soil.

Thickness and depth of the walls

Diaphragm walls are usually thicker and deeper than slurry walls, ranging from 0.6 to 1.5 metres in thickness and from 25 to 100 metres in depth. Slurry walls are usually thinner and shallower than diaphragm walls, ranging from 0.5 to 1.2 metres in thickness and from 15 to 30 metres in depth.

Quality and durability of the walls

Diaphragm walls have higher quality and durability than slurry walls, as they have better structural stability, water tightness and resistance to corrosion and seismic forces. Slurry walls have lower quality and durability than diaphragm walls, as they have more defects, cracks and leaks and are more prone to deterioration and damage.

These differences mean that diaphragm walls and slurry walls have different advantages and disadvantages, depending on the project requirements and site conditions. Diaphragm walls are more suitable for projects that require high-quality and long-lasting walls, such as tunnels, basements, dams and underground structures. Slurry walls are more suitable for projects that require low-cost and quick walls, such as temporary earth retention and water control.

Similarities between a Slurry Wall and a Diaphragm Wall

Despite the differences between slurry walls and diaphragm walls, they also have some similarities that make them both useful and effective for various construction projects. Here are some of the main similarities between them:

Construction technique

Both diaphragm wall construction and slurry wall construction are done in situ using slurry-supported trench excavation techniques, followed by the placement of reinforcing steel cages and the pouring of concrete. The trench is filled with a fluid mixture, usually bentonite or polymer, that stabilises the soil and prevents it from collapsing. The fluid is then replaced by concrete that is pumped from the bottom up using a pipe.

Function and purpose

Both slurry walls and diaphragm walls can serve as retaining structures, cut-off walls, or load-bearing elements in different projects. They can act as barriers to water and soil pressure and can also provide foundation support and structural stability. They can also be used for constructing tunnels, basements, dams and underground structures.

Advantages and benefits

Both slurry walls and diaphragm walls offer several advantages and benefits over other types of walls, such as:

- They are adaptable to various site conditions and geometries.

- They are durable and resistant to corrosion and seismic forces.

- They reduce the need for dewatering and excavation support systems.

- They minimise the disturbance to the surrounding environment and structures.

These similarities mean that slurry walls and diaphragm walls can be used interchangeably in some cases, depending on the project requirements and site conditions. However, it is important to consider the differences and trade-offs between them, as they may affect the performance and suitability of the walls for different projects.

Concluding thoughts

Slurry walls and diaphragm walls are both useful and effective for various construction projects, especially in areas with high groundwater tables or soft soil. They can serve as retaining structures, cut-off walls, or load-bearing elements in different projects. They can also be used for constructing tunnels, basements, dams and underground structures.

It is important to consider the differences and trade-offs between slurry walls and diaphragm walls and choose the best option for the project. By understanding the differences and similarities between these two types of walls, project leads can make informed decisions and achieve optimal results. For questions or feedback, please feel free to contact us at info@heritageinfraspace.in.

Frequently Asked Questions

A diaphragm wall is a reinforced concrete wall that is built in the ground panel by panel, usually under the protection of a slurry. It can act as a foundation, a retaining wall or a cut off provision for deep excavation. It is commonly used in areas with high groundwater tables or soft soil.

The difference between a diaphragm wall and a retaining wall is that a diaphragm wall is a deep structural unit that often acts as a supporting wall, while a retaining wall is a structure that holds back the ground. A diaphragm wall is essential in congested sites, while a retaining wall helps restrain soil to a slope that is not in its natural form.

Slurry walls are not permanent in the sense that they are not designed to last forever. They are usually constructed as temporary or intermediate structures that serve a specific purpose, such as soil retention, water control or foundation support. However, some slurry walls can be reinforced and integrated into the permanent structure, depending on the project requirements.