Water leakage is one of the most common and costly problems in construction projects, especially in deep basement structures. Water can seep through cracks and joints in concrete, causing damage to the structure and its contents. To prevent this, water stoppers are used to seal the joints and create a watertight barrier. Water stoppers are flexible strips made of various materials, such as rubber, metal or plastic.

Here, we will focus on PVC water stoppers, which are widely used for their durability, flexibility and resistance to chemicals and corrosion. We will explain how PVC water stoppers work, where they are used especially for diaphragm wall construction for deep basements.

What is a PVC water stopper

A PVC water stopper is a flexible strip made of plastic that acts as a physical barrier to water at concrete joints. It is designed to prevent water leakage and seepage in structures such as basements, water tanks, swimming pools, dams, bridges, tunnels and other underground constructions.

PVC water stoppers are made of polyvinyl chloride (PVC), which is a synthetic polymer composed of vinyl chloride monomers. PVC is one of the most widely used plastics in the world, due to its versatility, durability and low cost. PVC can be modified by adding various additives, such as plasticizers, stabilisers, fillers, pigments and lubricants, to enhance its properties and performance.

The PVC manufacturing plant of HIPL in action

PVC water stoppers are manufactured by extrusion, which is a process of forcing the molten PVC mixture through a die to form a continuous strip of the desired shape and size. The strip is then cut, spliced or welded to form the final product. PVC water stoppers are an essential component of any construction project that involves water retention or prevention. They ensure the structural integrity, safety and durability of the project.

Types of PVC water stoppers

PVC water stoppers are available in different types, depending on their shape, size and application. Some of the common types of PVC water stoppers are:

Dumbbell type

This type of PVC water stopper has a dumbbell-shaped profile, with two identical halves on both sides of a central bulb. It is suitable for expansion joints, where the movement of the concrete is expected. It can also accommodate vibrations and shocks.

Ribbed type

This type of PVC water stopper has a flat profile, with ribs on both sides. It is suitable for contraction joints, where the concrete is expected to shrink. It provides a firm grip and a large contact area with the concrete.

Centre bulb type

This type of PVC water stopper has a flat profile, with a bulb in the centre. It is suitable for construction joints, where the concrete is poured in stages. It allows for lateral and transverse movements of the joint.

Kicker type

This type of PVC water stopper is placed on the surface of the concrete, rather than embedded within it. It is suitable for situations where the reinforcement bars interfere with the installation of the embedded type. It is also used for retrofitting existing structures.

While many companies manufacture PVC water stoppers in India, we at Heritage Infraspace manufacture our own PVC water stoppers for our diaphragm wall construction projects.

HIPL has its own PVC water stopper manufacturing unit in Ahmedabad, Gujarat

PVC water stoppers in diaphragm wall constructio

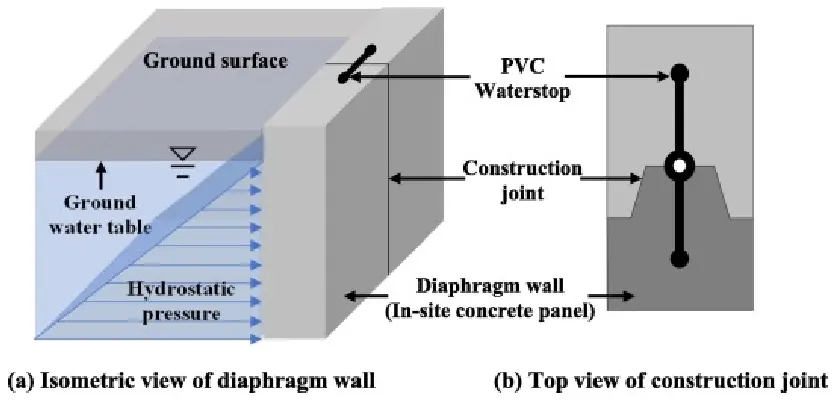

Diaphragm walls are a type of retaining wall that is used in construction projects where there is a risk of groundwater seepage. They are made of concrete and are installed underground. PVC water stoppers are used to seal the joints between the diaphragm wall panels and to prevent water from seeping through.

PVC water stoppers are designed to withstand high water pressure, accommodate movement in the joint and resist chemicals and corrosion. They are available in different shapes and sizes, depending on the type of joint and the direction of water pressure.

PVC water stoppers are installed at the centre or at the edges of the diaphragm wall panels, depending on the type of joint. They are embedded in the concrete and form a continuous seal along the joint. They can also be joined together by welding, splicing or using special connectors.

PVC water stoppers are an essential component of diaphragm wall construction, as they ensure the structural integrity, safety and durability of the project. They prevent water leakage and seepage, which can cause damage to the structure and its contents. They also reduce the risk of cracks and failures in the concrete.

Usage of PVC water stoppers in diaphragm wall construction is a very innovative way to prevent water leaks

To conclude

PVC water stoppers are flexible, durable and economical products that ensure the structural integrity, safety and durability of any construction project that involves water retention or prevention. If you are looking for high-quality PVC water stoppers in India, you can contact Heritage Infraspace India Ltd in Ahmedabad and we will be happy to assist you.

Frequently Asked Questions

Water stoppers made of PVC are designed to stop water from leaking or seeping through the joints of concrete structures, such as water tanks, tunnels, bridges, dams and basements. They create a seal that blocks water and protects the project from damage, risk and decay.

PVC water stopper rolls are available in different lengths, depending on the type and size of the water stopper. Ideally, their length is decided as per the Good For Construction (GFC) drawings. The length of the roll can also be customised according to the project’s requirements.

PVC water stoppers are available in different thicknesses, depending on the type and size of the water stopper. The standard thickness of a PVC water stopper is 8mm. The thickness of the water stopper affects its flexibility, strength and performance.