Diaphragm walls are continuous reinforced concrete walls constructed in the ground to support major construction activities such as dams, tunnel approaches, deep basements and enclosures. They act as a retaining wall, a support for the underground structure, a foundation or a cut-off provision to facilitate deep excavation.

In this blog, we will discuss the different types of diaphragm wall construction and their costs in India. Diaphragm wall construction cost varies depending on the size, depth and complexity of the project. We will also answer some frequently asked questions about diaphragm walls and their applications.

Types of Diaphragm Wall Construction

There are four types of diaphragm wall construction in India, depending on the method of excavation and concreting. They are…

Grabbed diaphragm wall

This type of diaphragm wall is constructed by excavating vertical panels under stabilising slurries using mechanical or hydraulic clamshell grabs. The grabs are suspended by a crane or a cable and can break any obstruction encountered in the soil. The trench is then filled with concrete after placing the reinforcement cage. This is a common method for basement diaphragm wall construction. The cost of grabbed diaphragm wall construction ranges from Rs 10,000 to Rs 15,000 per square metre.

Hydromill diaphragm wall

This type of diaphragm wall is constructed by excavating vertical panels under stabilising slurries using a hydromill cutter. The hydromill is a powerful tool that can cut through hard soil and rock layers. The trench is then filled with concrete after placing the reinforcement cage. This is a preferred method for metro diaphragm wall construction in India, as it can handle complex geology and high water pressure. The hydromill diaphragm wall construction price ranges from Rs 15,000 to Rs 20,000 per square metre.

different types of diaphragm walls fulfil various requirements of the projects

Precast concrete diaphragm wall

This type of diaphragm wall is constructed by inserting precast concrete panels into the trench after excavating it using grabs or hydromills. The panels are interlocked with each other and with the surrounding soil to form a continuous wall. This is a suitable method for diaphragm wall in dam construction, as it can resist high loads and seismic forces. The cost of precast concrete diaphragm wall construction ranges from Rs 20,000 to Rs 25,000 per square metre.

Steel-reinforced diaphragm wall

This type of diaphragm wall is constructed by inserting steel tubes or beams into the trench after excavating it using grabs or hydromills. The tubes or beams are then filled with concrete to form a composite wall. This is an alternative method for diaphragm wall construction in India, as it can provide higher strength and durability than conventional concrete walls. The steel-reinforced diaphragm wall construction price ranges from Rs 25,000 to Rs 30,000 per square metre.

Factors affecting diaphragm wall construction costs

The cost of diaphragm wall construction in India depends on several factors, such as:

Type of diaphragm wall

There are different types of diaphragm walls, such as slurry walls, soil mix walls and composite walls. Each type has its advantages and disadvantages and the choice depends on the project requirements and site conditions. Generally, slurry walls are the most expensive, followed by soil mix walls and composite walls.

Depth of the excavation

The deeper the excavation, the diaphragm wall construction cost would be higher. This is because deeper excavations require more materials, equipment and labour, as well as more complex engineering and safety measures.

Complexity of the project

The complexity of the project also affects the cost of diaphragm wall construction. For example, if the project involves curves, corners, or irregular shapes, the diaphragm wall construction will be more challenging and costly than a simple rectangular or linear excavation.

Various factors come into play when it comes to calculating the cost of diaphragm wall construction

Soil conditions

The soil conditions at the site influence the cost of diaphragm wall construction as well. For instance, if the soil is hard, rocky, or contaminated, the diaphragm wall construction will require more specialised tools and techniques, which will increase the cost. On the other hand, if the soil is soft, sandy, or clayey, the diaphragm wall construction will be easier and cheaper.

Environmental conditions

The environmental conditions at the site also play a role in the cost of diaphragm wall construction. For example, if the site is located in a high seismic zone, a coastal area, or a flood-prone area, the diaphragm wall construction will have to meet higher standards of quality and durability, which will raise the cost.

According to market estimates, the average cost of diaphragm wall construction in India ranges from Rs. 15,000 to Rs. 25,000 per square metre. However, this may vary depending on the factors mentioned above. Therefore, it is advisable to consult with experienced diaphragm wall and piling contractors in India who can provide accurate quotes and guidance on diaphragm wall construction for your project.

Having expert civil engineers on board can help cut ballooning expenses during construction

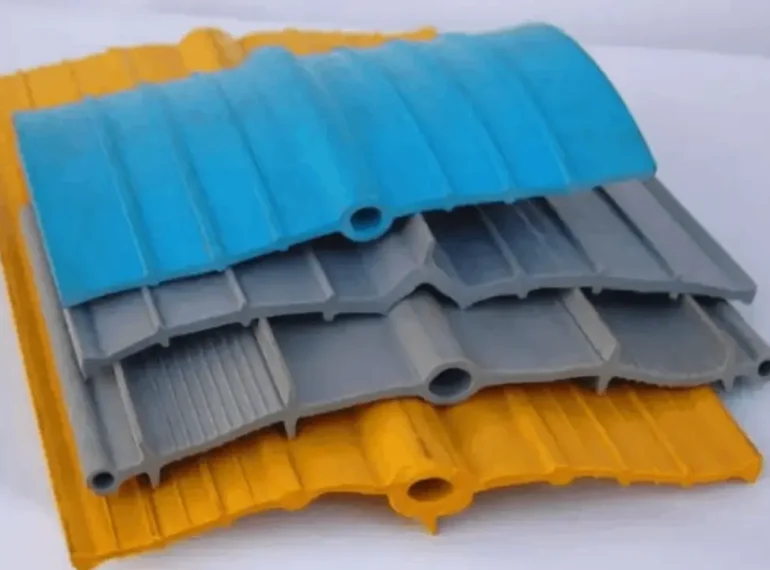

Diaphragm walls are also used for top down construction methods, which involves building the underground structure first and then constructing the above-ground structure later. This method reduces noise and dust pollution, saves space and time and improves safety and quality. Diaphragm walls also require PVC water stoppers to prevent water leakage between adjacent panels. PVC water stoppers are flexible strips that are embedded in concrete joints to seal them from water ingress.

Additional diaphragm wall construction costs

Apart from the diaphragm wall construction cost in India, there may be some additional costs that need to be considered, such as:

Site investigation cost

This includes the cost of conducting soil tests, groundwater tests and geophysical surveys to determine the soil conditions and design parameters for the diaphragm wall. The site investigation cost may vary depending on the complexity and size of the project.

Design and supervision cost

This includes the cost of hiring consultants and engineers to design and supervise the diaphragm wall construction. The design and supervision costs may depend on the scope and duration of the project.

Contingency costs

This includes the cost of unforeseen events or risks that may affect the diaphragm wall construction, such as delays, accidents, disputes, weather conditions, etc. The contingency cost may be estimated as a percentage of the total project cost.

While the diaphragm wall construction price can be estimated based on factors like the type of wall, depth of excavation, the complexity of the project, soil conditions and environmental conditions, it’s important to consider these additional costs for a comprehensive understanding of your total investment.

To conclude…

Diaphragm walls are an effective and versatile solution for various construction projects that require deep excavation and soil retention. They can be constructed using different methods and materials, depending on the site conditions and project requirements. The cost of diaphragm wall construction in India depends on several factors, such as the type of wall, the depth of excavation, the complexity of the project, the soil conditions, the environmental conditions and the additional costs.

If you are looking for a reliable and experienced partner for your next deep basement project, you can consult with Heritage Infraspace India Ltd (HIPL), the pioneers and leaders in diaphragm wall construction in India. They have the expertise and the equipment to deliver high-quality diaphragm walls at competitive prices.

Frequently Asked Questions

The choice of the type of diaphragm wall depends on several factors, such as the depth and width of the excavation, soil and groundwater conditions, structural loads and requirements, availability and suitability of equipment and materials and budget and time constraints. Therefore, it is advisable to consult with an experienced geotechnical engineering company like HIPL who can advise you on the best type of diaphragm wall for your project.

The duration of constructing a diaphragm wall depends on several factors, such as the size and shape of the excavation, type and method of diaphragm wall construction, site access and logistics, weather conditions, quality control and safety measures. While it may be difficult to give a general answer to this question, as a rough estimate, it may take around 90 days to construct a single basement diaphragm wall.

There are some ways to reduce any increase in the cost of diaphragm wall construction, such as conducting a thorough site investigation and design optimisation to avoid unnecessary or excessive excavation and concreting. Planning and scheduling the diaphragm wall construction efficiently and effectively to avoid delays and wastage, which means you save on additional costs.