Diaphragm wall construction is a technique that uses reinforced concrete walls to create deep basements for various projects. It is one of the most reliable and cost-effective methods of retaining soil and water in challenging ground conditions. In this blog, we will explore why diaphragm wall construction is superior to other options and how it can secure your project.

Types of Retaining Systems for Underground Construction

Sheet piling

Sheet piling is a method that involves driving interlocking steel sheets into the ground to form a wall. Sheet piling is a fast and simple technique that can be used in soft and sandy soils. However, sheet piling has many disadvantages, such as low strength and durability, high noise and vibration, high ground movement and settlement, low water tightness and limited excavation depth and width.

Secant piling

Secant piling is a method that involves drilling and concreting overlapping piles into the ground to form a wall. Secant piling is a more robust and watertight technique than sheet piling and can be used in hard and rocky soils. However, secant piling also has many drawbacks, such as high cost and time, difficult site access and logistics and quality control and inspection issues.

Soil nailing

Soil nailing is a method that involves inserting steel bars or rods into the ground to reinforce the soil and create a wall. Soil nailing is a cheap and easy technique that can be used in sloping and unstable soils. However, soil nailing has many limitations, such as low strength and durability, low water tightness and dependence on the soil conditions and properties.

Diaphragm wall

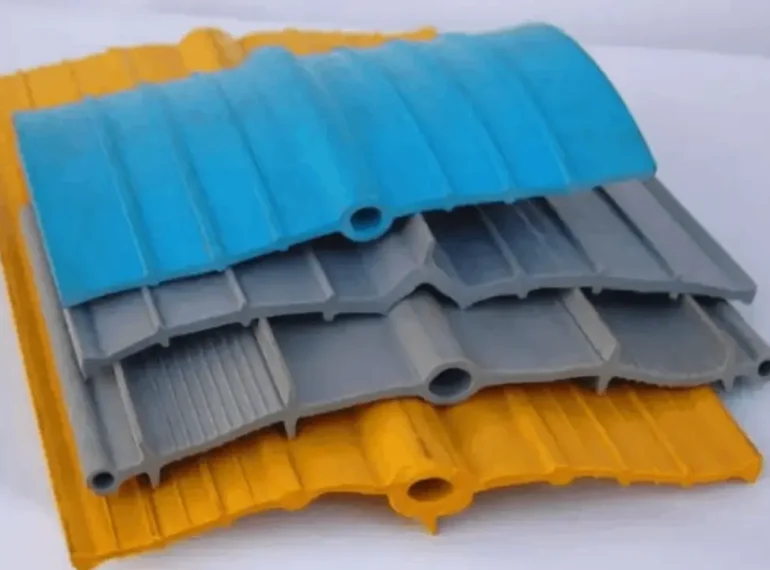

Diaphragm walls are a method that involves excavating a narrow trench in the ground and filling it with a fluid called bentonite slurry. The slurry acts as a temporary support for the trench and prevents it from collapsing. Then, a steel cage is lowered into the trench and concrete is poured to form a wall. Diaphragm walls are a versatile and adaptable technique that can be used in various soil types and site conditions. They can also be designed to suit different loads and geometries, depending on the project requirements.

Compared to these alternatives, diaphragm wall construction is a superior and more reliable technique that can provide better results and outcomes for deep basement construction.

What makes diaphragm wall construction better than other retaining methods?

Diaphragm wall construction offers many advantages over other retaining systems, such as:

High strength and durability

Diaphragm walls are made of reinforced concrete, which can withstand high pressures and loads. They are also resistant to corrosion, erosion and seismic forces. Diaphragm walls can last for decades without requiring much maintenance or repair.

Low noise and vibration

D-wall construction does not involve any drilling, hammering or blasting, which can cause noise and vibration problems for nearby buildings and residents. The excavation and concreting are done in a controlled and quiet manner, minimizing the disturbance to the environment and the public.

Minimal ground movement and settlement

Diaphragm wall construction does not disturb the surrounding soil as much as other methods, such as sheet piling or secant piling. The bentonite slurry acts as a lubricant and a barrier, reducing the friction and the leakage of soil and water. This results in less ground movement and settlement, which can damage the existing structures and utilities.

High water tightness

Diaphragm walls are designed to have low permeability and high water tightness, which can prevent groundwater from seeping into the basement or the structure. This can reduce the risk of flooding, dampness and water damage. D-wall can also be used to control the groundwater level and pressure, which can affect the stability and safety of the project.

Large excavation depth and width

Diaphragm wall construction can achieve large excavation depths and widths, which can accommodate complex and large-scale projects. Diaphragm walls can be constructed up to 100 meters deep and 1.5 meters thick, depending on the site conditions and the equipment available. Diaphragm walls can also be shaped to fit different curves and angles, creating flexible and customised solutions.

Top down construction

Diaphragm wall construction is compatible with the top down construction approach, which is a method of building the superstructure and the underground levels simultaneously. This can reduce the construction time and the disruption to the surrounding areas. Top down construction involves using the diaphragm walls as temporary supports for the excavation and the superstructure loads while casting the basement slabs as the excavation progresses.

What are the Challenges of Diaphragm Wall Construction and How to Overcome Them?

D-wall construction is not without its challenges and limitations, such as:

High cost and time

Diaphragm wall construction is a complex and labour-intensive process that requires specialized equipment and skilled workers. It also involves multiple stages and quality checks, which can increase the cost and time of the project. However, these costs and time can be offset by the long-term benefits and savings that d-wall construction provides, such as lower maintenance, higher performance and greater safety.

Difficult site access and logistics

Diaphragm wall construction requires a large working area and a clear access route for the equipment and materials. It can be difficult to perform d-wall construction in congested and urban areas, where space and traffic are limited. However, these challenges can be overcome by careful planning and coordination, as well as using smaller and more efficient machines and tools.

Quality control and inspection

Diaphragm wall construction requires strict quality control and inspection to ensure that the walls are constructed according to the specifications and standards. Any defects or deviations in the walls, such as cracks, voids or misalignments, can compromise the integrity and performance of the structure. Therefore, it is essential to use advanced techniques and technologies, such as sonic logging, cross-hole sonic logging and ultrasonic testing, to monitor and verify the quality of the walls.

To conclude

Diaphragm wall construction is the best solution for deep basement construction, as it offers many benefits over other retaining systems, such as high strength and durability, low noise and vibration, minimal ground movement and settlement, high water tightness and large excavation depth and width. D-wall construction also has some challenges and limitations, such as high cost and time, difficult site access and logistics and quality control and inspection, but they can be overcome by using proper techniques and technologies and choosing the right construction company.

If you are looking for a construction company that can provide diaphragm wall construction with quality and efficiency, look no further than Heritage Infraspace Pvt Ltd (HIPL). HIPL is the pioneer of diaphragm wall construction for deep basement construction in India, with over 30 years of experience and expertise in the field. HIPL has completed many diaphragm wall construction projects for various sectors, such as commercial, residential, industrial and infrastructure, across India. HIPL has the latest and most advanced equipment and technology for diaphragm wall construction, as well as a qualified and experienced team of engineers, technicians and workers who can deliver diaphragm wall construction with professionalism and competence.

If you want to know more about diaphragm wall construction and how it can secure your project or if you want to discuss your basement construction project plans with us, please email us at info@www.heritageconstruction.in.

Frequently Asked Questions

A diaphragm wall is a continuous wall made of reinforced concrete, while a secant wall is a series of overlapping piles made of concrete or steel. A diaphragm wall has higher strength and water tightness than a secant wall, but also higher cost and time. A secant wall has lower noise and vibration than a diaphragm wall, but also lower quality and accuracy.

The cost of diaphragm wall construction in India depends on various factors, such as the site conditions, the wall dimensions, the project complexity and the construction company.

The duration of diaphragm wall construction in India also depends on various factors, such as the site conditions, the wall dimensions, the project complexity and the construction company. However, a rough estimate is that diaphragm wall construction takes around 2 to 3 weeks per panel of wall, where a panel is typically 2.5 to 3 meters wide and 20 to 30 meters deep.