When it comes to the construction of dams, the safety and stability of the structure are of paramount importance. The diaphragm wall in dam is an essential component, which helps to retain the water and prevent seepage. There has been a long-standing debate over whether drilling and grouting are necessary for constructing diaphragm walls in dams. In this blog post, we will explore the topic of drilling and grouting in dam construction and examine whether they are a requisite.

What are drilling and grouting?

Drilling and grouting are two common techniques used in construction projects to increase the stability and strength of soil and rock. Drilling involves the use of a drill to create a hole in the ground, while grouting involves injecting a fluid material, such as cement or a chemical solution, into the hole to fill any gaps or voids. This process creates a strong, stable foundation for the structure being built.

There are several drilling and grouting techniques used, depending on the geological conditions and the desired outcome. Some of the common drilling and grouting techniques are:

Drilling activity in progress at a HIPL project site

Jet Grouting: In this technique, a high-pressure jet of grout is injected into the soil or rock to create a column of grouted soil, followed by inserting anchors in construction. The columns can be used to create a diaphragm wall or to strengthen the foundation by increasing the bearing capacity.

Cement Grouting: In this technique, a mixture of cement, water and additives is injected into the soil or rock to fill any voids or gaps and create a solid foundation. The cement grout can be injected under pressure or by gravity, depending on the depth and the required strength.

Chemical Grouting: In this technique, chemicals are injected into the soil or rock to create a stable barrier. The chemicals react with the soil or rock to create a solid mass and prevent the flow of water and soil particles.

Where are drilling and grouting techniques used?

Drilling and grouting techniques are commonly used in various construction projects, including the construction of tunnels, foundations and dams. In dam construction, drilling and grouting can be used to create a solid foundation and prevent water from seeping through the dam. This is achieved by creating a diaphragm wall using a combination of drilling and grouting techniques.

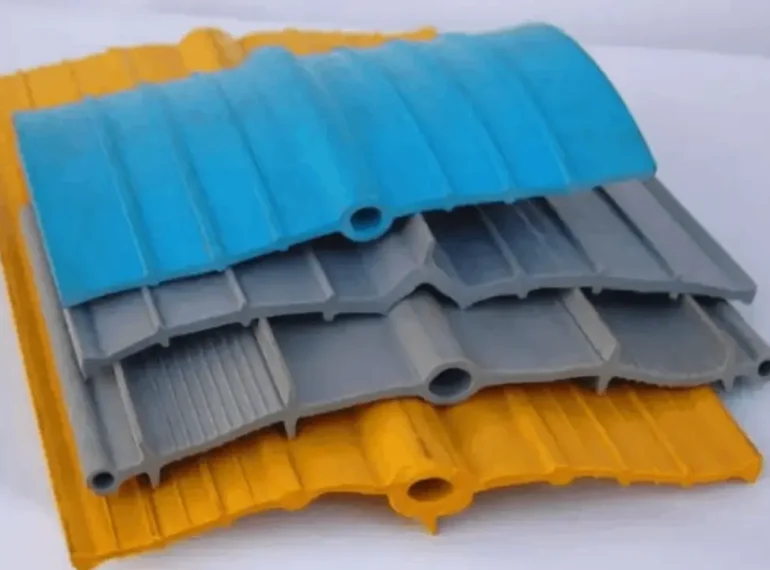

What are Diaphragm Walls?

Diaphragm walls are reinforced concrete walls that are constructed by excavating a trench in the soil, installing reinforcement cages and filling the trench with concrete. They are commonly used to create underground structures, such as basements, tunnels and underground parking garages.

How do diaphragm walls work in dam construction?

Dam construction in action somewhere in North India

These large, reinforced concrete walls are typically used in the construction of dams and other large-scale structures. These walls are constructed by using a top down construction method, which involves excavating a trench and installing anchors or piles to stabilise the surrounding soil. The diaphragm wall is then constructed by pouring concrete into the trench, which forms a continuous, watertight barrier.

In dam construction, diaphragm walls are used to strengthen the foundation by providing a stable and watertight barrier between the dam and the underlying soil or rock.

The stability of a dam foundation is critical, as any failure or instability can have catastrophic consequences. Diaphragm wall construction strengthens the foundation by preventing the flow of water and soil particles through the foundation, which can cause erosion and instability. They also increase the bearing capacity of the foundation by distributing the load of the dam over a larger area.

Why is it not required to have drilling and grouting in dam construction?

While drilling and grouting are effective techniques for creating a stable foundation, they are not always necessary in dam construction. Diaphragm walls are designed to be watertight and prevent water from seeping through the dam. If the soil surrounding the dam is stable and has low permeability, drilling and grouting may not be required. Additionally, drilling and grouting can be time-consuming and expensive, which can increase the overall cost of the project.

Cantilever Diaphragm Walls are another method of constructing diaphragm walls in dams. They do not require any form of anchoring, making them a cost-effective and efficient solution for dam construction. The cantilever diaphragm wall is constructed using a similar top-down construction method, where the wall is built in stages by pouring concrete into the trench. The stability of the wall is ensured by the weight of the concrete and the soil pressure exerted on the wall. This method of construction eliminates the need for drilling and grouting and makes the construction process faster and more economical.

In Conclusion..

Drilling and grouting techniques are effective methods for creating a stable foundation in construction projects, including dam construction. However, they are not always necessary and can be time-consuming and expensive. Diaphragm walls can be constructed using a top-down construction method, which provides an alternative to drilling and grouting and can be just as effective in creating a stable foundation for the dam. Cantilever diaphragm walls offer a cost-effective and efficient solution for dam construction, eliminating the need for piling construction anchoring, drilling and grouting. Ultimately, the decision to use drilling and grouting in dam construction will depend on the specific site conditions and the design of the dam.