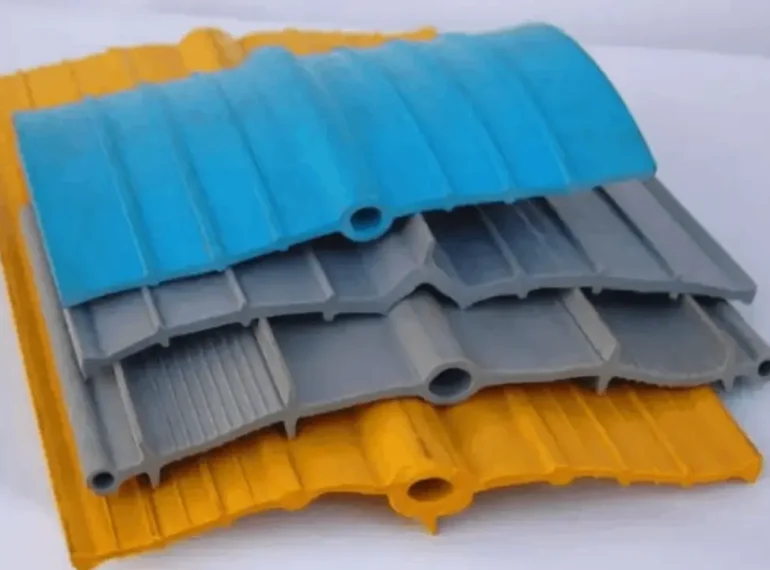

Apart from being the pioneers of diaphragm wall construction for deep basements, what makes Heritage Infraspace India Ltd rank as the one of the top construction company in India is their approach to safety on site. Safety on construction sites protects the workers and keeps the public safe.

The construction sites commissioned to HIPL are typically congested locations in bustling cities with high pedestrian and vehicular traffic. Inadequate safety procedures could lead to mishaps involving construction employees, heavy equipment and onlookers, placing them in severe and sometimes life-threatening danger.

Here are some of the steps HIPL follows, as a responsible diaphragm wall construction company in Ahmedabad, India, to ensure the safety of workers and general people around the site, right from implementing a health, safety and environment plan to an internal checklist of to-dos by the safety team of HIPL.

General Workers’ Safety

Every member on the ground, including the labourers and engineers, is provided with reflective safety jackets, standard safety helmets and safety shoes with steel toes.

Those working in reinforcement get hand gloves, and shoulder pads as they carry heavy and long rods of steel bars and welded wire fabrics.

Welders are provided with a proper faceguard, gloves and safety aprons, to protect them from the sparks flying off the metal during the process.

Teams working with concrete in Diaphragm wall construction are also provided with special gum boots and hand gloves.

Site Safety Protocols

At every HIPL construction project site, a safety officer assists the project manager in implementing safety guidelines and reviewing risk assessment. Together they conduct multiple levels of safety inspections at site on a continuous basis, making on-the-spot corrections.

Before the beginning of any project operations, the safety officer and the project manager conduct a safety meeting with all staff members. This session educates everyone involved in the project about the various steps to be taken to avert any untoward incident that might put anyone in danger or cause loss of property.

Hard Barrication is done prior to construction commencement. Clear and visible signages like Deep Excavation, Non PPE Zone, Active Drilling in Process, Electrical DG Set Zone, Cage Making in Progress etc are placed to ensure site identification.

The on-site safety checklist includes:

- Proper covering for light and power lines to avoid open flames and electrical short-circuiting.

- Electric lines and light are insulated and secured completely.

- Ensuring the presence of doctors and medical equipment at the worksite.

- Availability of sufficient water supply and firefighting equipment.

- Maintenance of tools and machines used in building the best concrete diaphragm walls in india

- Efficient communication system inside at site to send and receive essential information.

- Ensure the workability and efficiency of power systems, communication systems, lighting and safety devices regularly.

- Installation of signboards for safety and identification on site

- The perimeter around the Hydraulic rig machine has to be secured.

- Base or MS Plate is placed below the rigging machine, to ensure soil collapse does not deter work.

- MS Tanks for the polymer mixing need to be on a smooth level.

- There’s always an ambulance and first aid kit. Safety container with all needed medical kits.

Safety in and around heavy equipment.

What makes HIPL one of the top construction company in India is its usage of state-of-the-art, modern construction machinery and equipment. And those working with these machines are provided with special training for their safe usage and execution of the tasks. HIPL runs a thorough background check and hires only competent and experienced equipment operators and foremen.

All the slings, lifting belts and D-Shackles used in construction activity are tested and approved in two levels, first by the manufacturer and secondly by a third party agency hired for testing and certification by HIPL.

Fire safety

The first and foremost step when it comes to fire safety, the safety officer ensures that fire extinguishers are provided at all the temporary facilities. These are inspected by him/her every month to ensure they are in good working condition.

Every equipment/machine is provided with at least one fire extinguisher (10 lb. capacity, dry powder type) located at the access/exit door. No point within any office/cabin is more than 20 metres from a fire extinguisher. A hot work permit is also acquired from the client before commencement of the work.

Second, all electrical connections are routed through earth leakage circuit breakers (ELCB) and all diesel generator sets have proper earthing done with salt and charcoal. Further the oxygen and Dissolved acetylene(DA) gas cylinders used gas welding machines are kept on a solid ground to prevent tilting and subsequent leakage.

The construction area is also ensured to be a strict no-smoking zone.

Safety is one of the strongest pillars alongside smart execution, modern technology and honesty, on which Heritage Infraspace India Ltd or HIPL thrives. The ultimate goal of HIPL in every project it works on, is to ensure zero lost-time, injury or accident. As one of the best construction companies and the most trusted Diaphragm Wall Construction Company in Ahmedabad and India, for us safety on the construction site is vital to protecting our worker team and the public, and creating a culture of safety in the company while ensuring we finish our projects on time.

If you would like to know more about our safety methods or anything related to our diaphragm wall construction projects in India or across the world reach out to us on email at info@www.heritageconstruction.in