Heritage Infraspace India Limited (HIPL) is known as the pioneers of diaphragm wall construction for deep basements in India. As one of the top construction companies in India, HIPL has worked on several residential and commercial projects collaborating with prominent names from the real estate industry. One such commercial complex project is the Adarshini real estate pvt ltd under Hines in Gurgaon.

Here’s a deep-dive into the observations made, challenges faced, and solutions provided during the construction phase of this project.

Adarshini & Hines – The client

Aadarshini Real Estate Developers Private Limited is a wholly-owned subsidiary of DLF Home Developers Limited, a part of the DLF (Delhi Land and Finance) Limited, one of the largest commercial and residential real estate construction companies in India.

Hines is a privately owned global real estate investment, development and management firm, with a presence in 285 cities in 28 countries and $90.3 billion of investment assets under management and more than 114.2 million square feet of assets for which Hines provides third-party property-level services.

Adarshini and Hines combined forces together to build an exceptional and modern commercial space in Gurgaon near the prominent Income Tax complex, to cater to the changing business landscape of India and its growing demand of workspaces that fulfil the requirements of the globally connected enterprises working round the clock.

Projects awarded to HIPL for this project

HIPL was first awarded with a project to build diaphragm walls, conduct anchoring for soil and the requisite excavation activities for the North Parcel in 2020. It took HIPL close to 1 year to complete this project.

Upon completion of the North Parcel, HIPL was awarded a similar project at South Parcel, commissioning them with the construction of diaphragm walls, soil anchoring and excavation.

The excavation activities for diaphragm wall projects are usually commissioned to a third party by the client, but in this case, HIPL was assigned with the excavation activities too, given that we had all the required equipment and manpower to execute it.

This is one of the biggest commercial projects HIPL has worked on. What makes this project unique, is that HIPL engineers used retractable anchors, something which was innovative and executed for the first time on a project of this scale and size.

Challenges in this project

One of the biggest technical challenges faced in this project was the size of the perimeter on which the diaphragm wall was to be built. Apart from that, ramping the soil was also challenging in terms of execution, given the depth of the project.

Supervision in every stage, in every aspect was extremely crucial. The lead engineers were present at the location, guiding, overseeing and ensuring perfection in execution at all the times.

This, because the first leg of the project was being conducted during the monsoons and precautions for the safety of the workers and neighbouring structures were important. One of the most important buildings next to the project site was the Income Tax complex.

Constant rains were a cause of worry. But our engineers and team of workers did everything required as a part of the monsoon precautions on the sides of the perimeter, to ensure all the water drains away and no water gets percolated behind the constructed diaphragm wall.

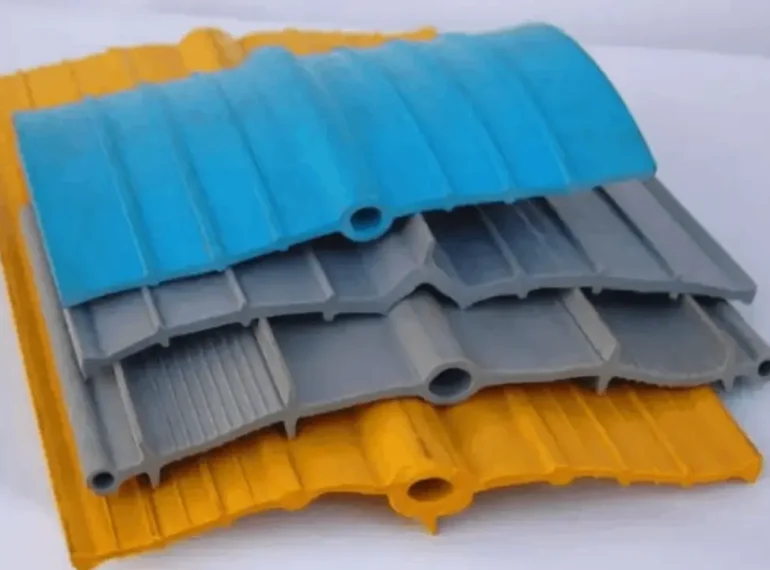

We used a crystalline mix in the concrete to resist the seepage from behind the diaphragm wall.

Crucial observations made by HIPL

The site was on virgin land, which meant there were no surprises to be expected, unlike the ones built on previously constructed plots, where risks of damaging pipelines or wirings were imminent.

Maintaining the timeline and completing the deadline was crucial, as all the machinery, equipment and other resources came with a standing cost, and any extension on the duration of the project meant additional overheads.

The stoppage of construction work for a brief period by the NGT (National Green Tribunal) to control the pollution in Delhi and other surrounding areas did come across as a hindrance, especially in the ongoing South Parcel construction. But all the pre- planned construction activities were completed with perfection and within the assigned deadline.

Solutions provided by HIPL

HIPL conducted the initial excavation activity with its own manpower and equipment for the diaphragm wall construction. It also provided soil management and innovative soil anchoring solutions along with the D-wall construction.

Gurgaon is a thriving commercial region near Delhi, which meant managing traffic to avoid any hindrance to the construction was another aspect managed well by the HIPL team on ground.

Equipment and technologies used by HIPL in this project

HIPL used 3 Casagrande B200 Diaphragm Wall Rigs for effective and quick progression of work, while the H22 rotary head has a maximum torque output of 210 kNm and speed up to 34 RPM.

Apart from these, the team also used JCB earthmovers to excavate the soil and multiple dumper trucks to carry these soil to a safe spot, away from the public spaces around.

Results

The North Parcel was completed within a year of being allotted in 2020. Impressed by the way this particular project was completed, Adarshini & Hines awarded HIPL with the same contract for the South Parcel of the same project.

The South Parcel, awarded to HIPL in 2022, is scheduled to be completed in 6 months’ time. It is an ongoing project.

To know more about the projects or to collaborate with us on your upcoming projects, get in touch with us today. Send us an email on info@www.heritageconstruction.in